When it comes to roofing systems for flat and low-slope buildings, few options have stood the test of time like Built-Up Roofing (BUR). Commonly called a “tar and gravel roof”, BUR has been used for over a century on commercial, industrial, and multi-family buildings.

Why? Because it’s durable, cost-effective, and proven to protect against water, sun, and weather damage. In this guide, we’ll explain what BUR is, how it works, and whether it’s the right choice for your property.

What is Built-Up Roofing (BUR)?

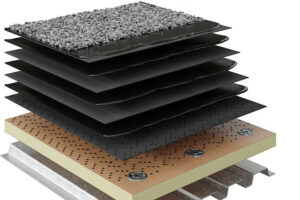

Built-Up Roofing is one of the oldest flat roofing systems still in use today. The name comes from the way the roof is built — by applying multiple layers of bitumen (asphalt or tar) and reinforcing fabric, topped with gravel or a protective coating.

This layered design creates a strong, waterproof barrier that resists leaks and stands up to heavy foot traffic, UV rays, and harsh weather. Unlike newer single-ply membranes (like TPO or EPDM), BUR has decades of proven performance.

Components of a BUR System

A BUR roof is more than just tar and gravel. It’s a carefully layered system made up of:

- Base Sheet – The first layer applied to the roof deck, creating a foundation.

- Bitumen (Asphalt or Tar) – The adhesive that binds the system together, applied hot, cold, or using coal tar.

- Reinforcement Layers – Usually fiberglass or organic felt sheets, alternating with bitumen for strength.

- Surfacing Layer – Gravel, mineral cap sheets, or reflective coatings that protect the roof from sunlight, fire, and weather.

These layers can be adjusted depending on the building’s needs. A thicker system with more plies generally lasts longer.

Advantages of Built-Up Roofing

BUR is popular for good reason. Some of the biggest benefits include:

- Proven Longevity – With proper installation and care, a BUR roof can last 20–30+ years.

- Excellent Waterproofing – Multiple layers provide extra protection against leaks.

- UV and Weather Resistance – Gravel or coatings shield the roof from sun and storms.

- Fire Resistance – The materials used naturally slow the spread of fire.

- Low Maintenance – Regular inspections and cleaning keep it in good shape.

- Cost-Effective – While the upfront investment can be moderate, BUR’s long lifespan makes it a smart choice.

Disadvantages of Built-Up Roofing

BUR isn’t perfect for every building. Some potential drawbacks include:

- Heavy Weight – Multiple layers add weight, so the structure must support it.

- Installation Time – BUR takes longer to install compared to single-ply systems.

- Mess and Fumes – Hot asphalt can produce strong odors during installation.

- Not for Every Roof Type – Works best on flat or low-slope roofs, not steep ones.

BUR vs. Other Flat Roofing Options

Many property owners compare BUR to other roofing systems. Here’s how it stacks up:

- BUR vs. Modified Bitumen – Modified bitumen is similar but uses fewer layers, making it lighter and easier to install. BUR is generally thicker and longer-lasting.

- BUR vs. TPO – TPO is a single-ply membrane, faster to install, and highly reflective for energy savings. BUR offers more durability but less energy efficiency.

- BUR vs. EPDM – EPDM (rubber roofing) is flexible and cost-effective. BUR, however, has better resistance to punctures and heavy traffic.

Best Applications for BUR

BUR is most commonly used on:

- Commercial Buildings – Warehouses, schools, hospitals, and shopping centers.

- Industrial Facilities – Factories and manufacturing plants.

- Multi-Family Housing – Apartment buildings with flat roof sections.

It’s rarely used in residential single-family homes unless there are flat roof portions.

Maintenance and Lifespan of BUR

Like any roofing system, BUR lasts longer with proper care. Here’s what property owners should do:

- Schedule annual roof inspections to catch small issues early.

- Keep drains and gutters clear to prevent standing water.

- Remove debris and check gravel coverage.

- Re-coat or repair worn areas as needed.

With good maintenance, a BUR roof typically lasts 20–30 years, sometimes longer.

Cost of Built-Up Roofing

The cost of a BUR roof depends on several factors:

- Roof size and accessibility

- Number of plies (layers) used

- Type of surfacing (gravel vs. coatings)

- Local labor and material costs

On average, BUR installation runs $4–10 per square foot, making it competitive with other flat roofing systems. The long lifespan makes it a cost-effective option over time.

Is Built-Up Roofing Right for You?

Built-Up Roofing is a great option if:

- You own a commercial or industrial building with a flat roof.

- You want a proven system with a track record of reliability.

- Your structure can support the added weight.

However, if you need faster installation, a lighter system, or greater energy efficiency, options like TPO or modified bitumen might be better.

Final Note

Built-Up Roofing (BUR) remains a tried-and-true roofing system for flat and low-slope buildings. With multiple layers of protection, it provides excellent durability, leak resistance, and long-term value.

At Hostetler Roofing, we’ve been installing and maintaining BUR systems across Arkansas and the Ark-La-Tex region since 1983. Whether you need a new installation, maintenance, or a roof inspection, our experienced team is ready to help.

Contact us today to schedule a free roof inspection and estimate.

You May Also Like To Read: Spray Foam Roofing: What is it?